Our work is in our DNA

It all started in 1919 when Walter J. Larkin left his position with Ford Motor Company and took his family west to Los Angeles, California. Just one year later, in 1920, Walter started his own company in the city he now called home. For almost twenty years, Southwest Manufacturing (1920 – 1938) provided machining services with mills and lathes.

The family story continues in the late 1930’s when Walter’s son, Richard, took a position with Northrup Company as their Materials Manager. As it turned out, Walter’s children inherited his entrepreneurial spirit and a new Larkin company was born just five years later in 1943.

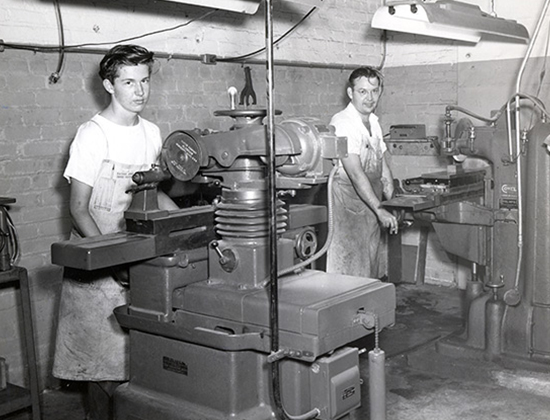

O&M Machine Company (1943 – 1965) was co-founded by Richard, Peggy and Walter J. Larkin, but they didn’t have access to the kind of facilities Larkin Precision Machining runs these days. O&M Machine Company started in an 800-square foot back room behind the O&M Gas Station, but from there the Larkin family business only grew. By the 1960’s they had over 250 employees and were operating out of several buildings that encompassed an impressive 85,000 square feet.

From 1965 to 1990, O&M Machining became the Richlar Company under the guidance of Richard Larkin II who continued the family tradition of supporting Air Force contracts. During this time, the company began developing new designs for defense projects, focusing on hydraulic and hoist applications.

Finally, in 1999, Rob, Seth and Jon Larkin estabed a business partnership that launched Larkin Precision Machining. This current generation of impassioned entrepreneurs has focused on developing strategic supplier partnerships with our core customers.

NOTABLE PROJECTS

We’re proud of the work we do on every job, but these are the projects that helped make Larkin Precision Machining what it is today.

- The Consolidated PBY Catalina Sea Plane

- O&M Machine Company helped develop and manufacture the aft bubble modification for this aircraft.

- The C124 Cargo Plane

- Developed and manufactured by Douglas Aircraft in Long Beach, California, O&M designed and manufactured air-cargo loading equipment for this transport aircraft in 1960. On top of that, O&M delivered 20 set per month for 20 years.

- Convair Project

- O&M was awarded a contract for the horizontal and vertical stabilizers and missile rack of this F106 Aircraft.

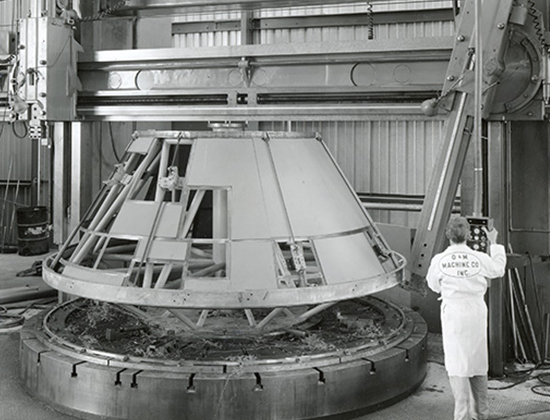

- The Apollo Space Capsule (1962)

- Rockwell International awarded the opportunity to manufacture the space capsule shell to O&M, a task they accomplished by machining it on an 18-foot vertical-boring mill.

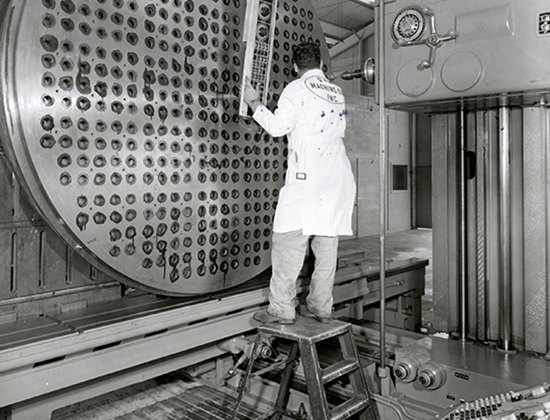

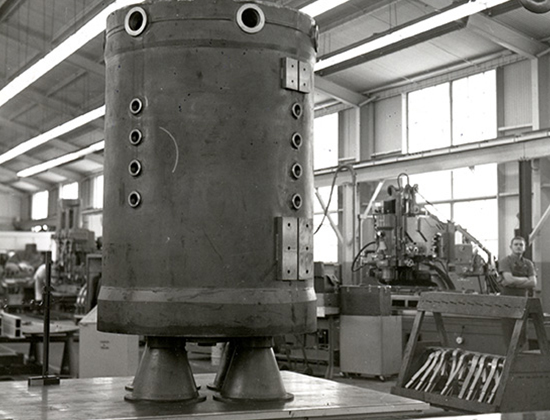

- The Peach Bottom Reactor Project

- General Atomic chose O&M to help design and manufacture the charging machine and core plates that made unloading nuclear rods possible.

Industry-Leading Certification